We meet the most diverse expectations

Products and Services

A leader in technology

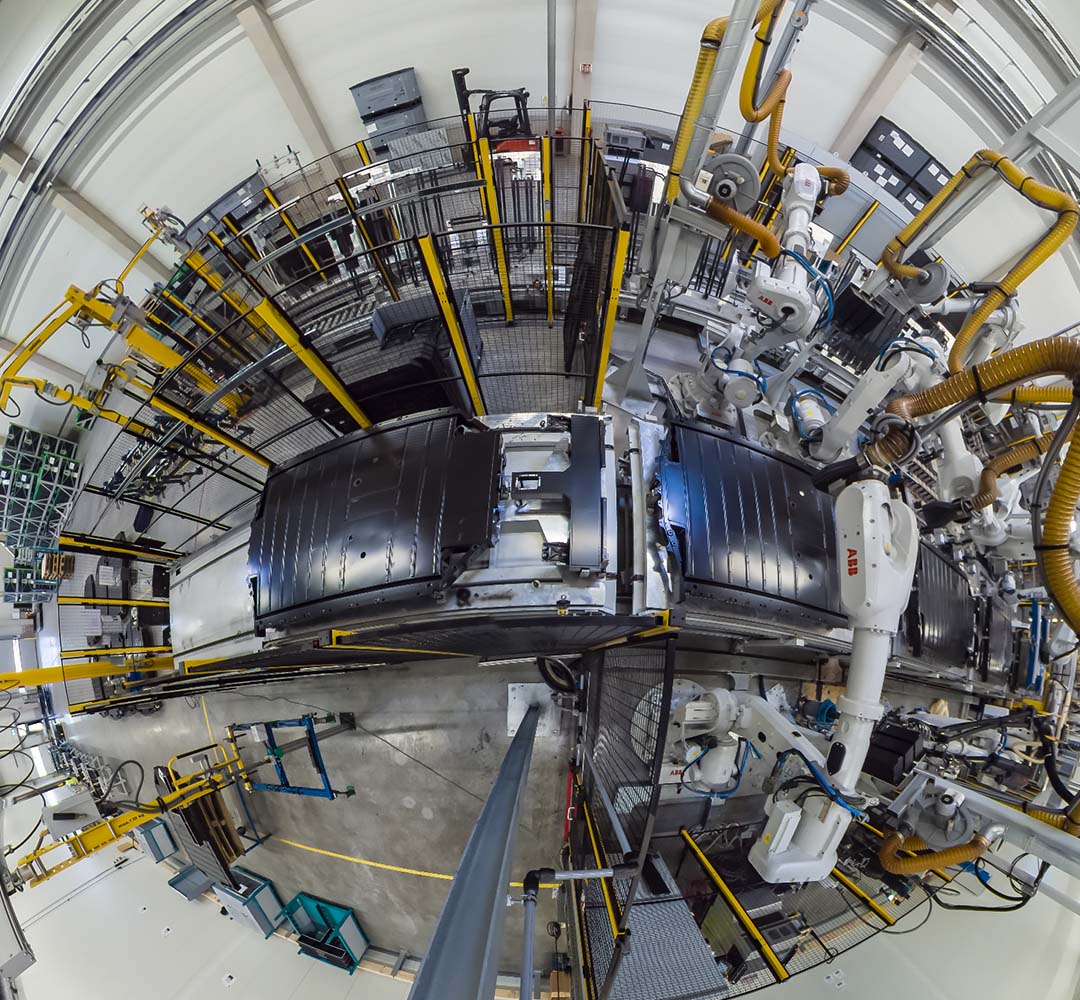

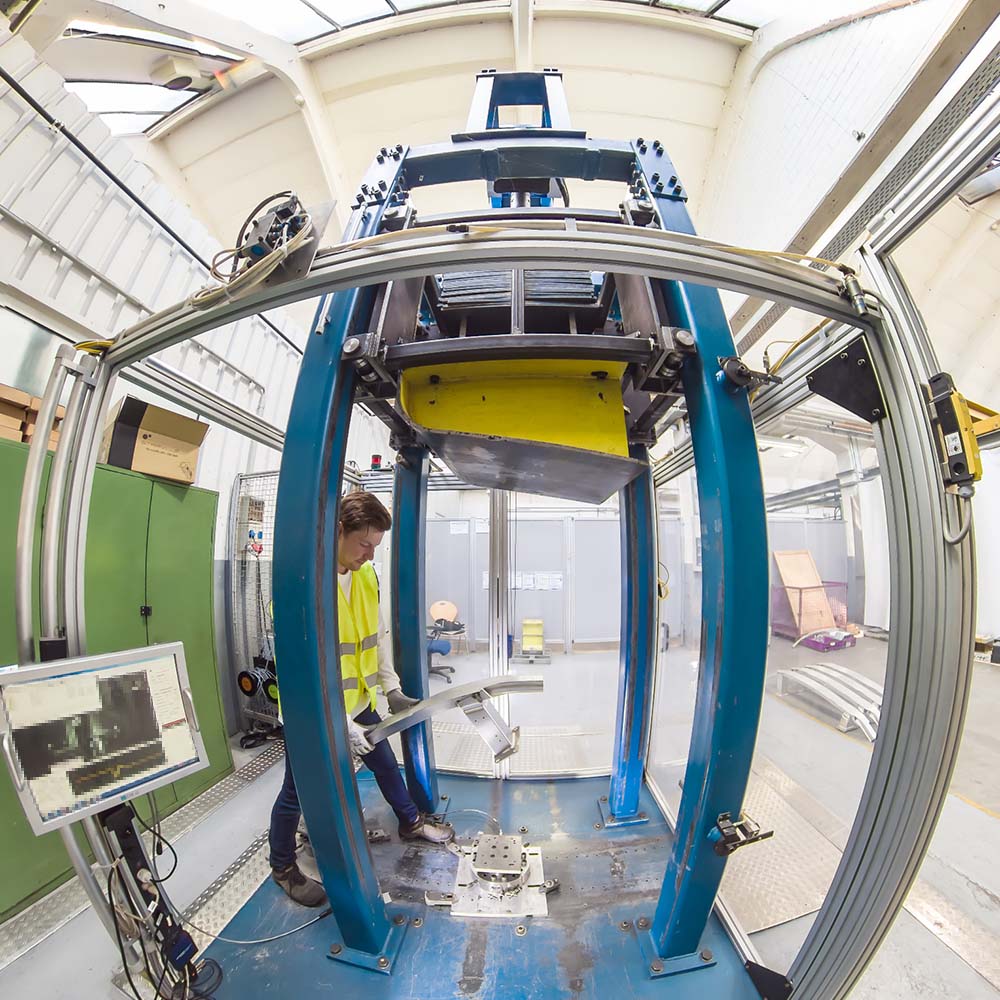

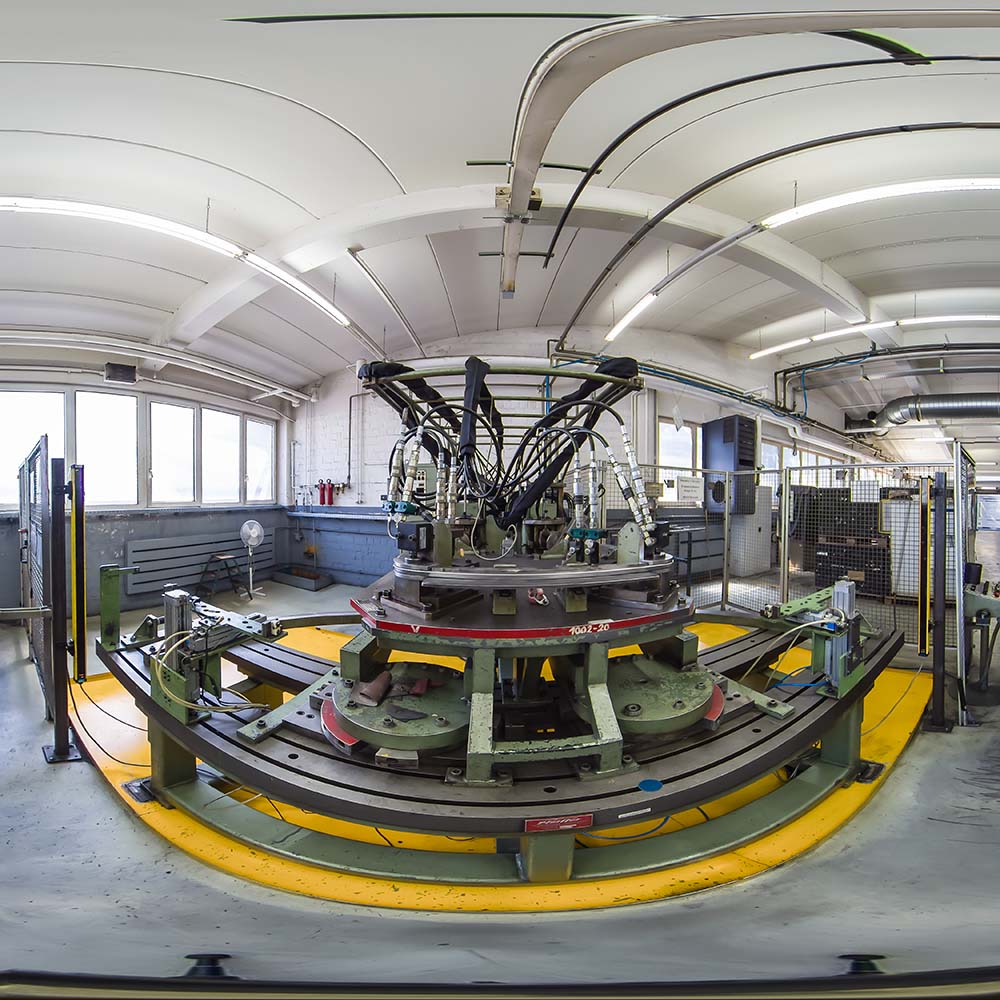

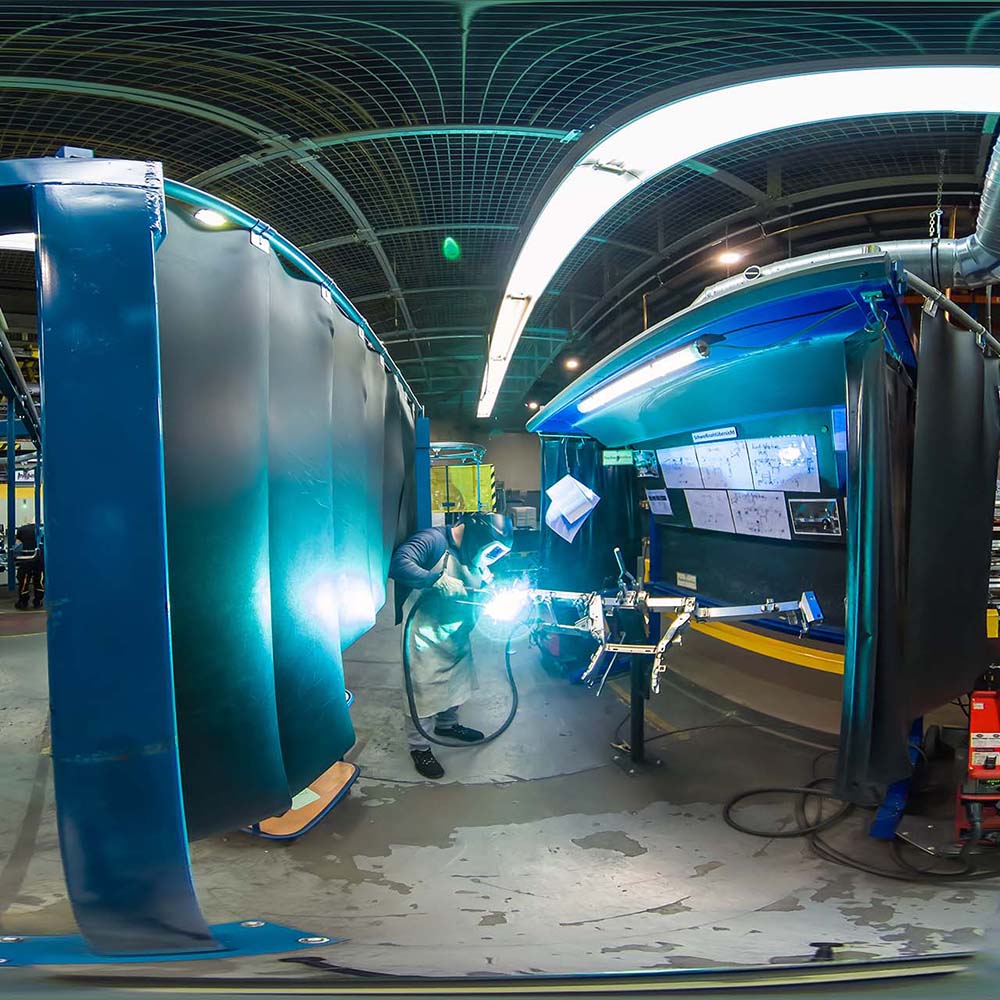

In addition to our expertise as a long-standing automotive supplier, the success of our innovational strength is based on the number of new technologies: The combination of the most modern production lines, agility in all processes and Industry 4.0 secures our decisive advantage over the competition.

Leading premium marques trust our product portfolio of battery cases, crash management systems, structural components, door components and tailgate structures.

As a full-service supplier, we stand for holistic process support – starting with development, through design to manufacturing in automotive lightweight construction.

x E-MOBILITY IN SERIES

x WORLDWIDE R&D

service standard

%